Improved line efficiency & quality

Improved line efficiency & quality

Improved line efficiency & quality

Improved line efficiency & quality

The discrete manufacturing industry is prone to globalized supply chains, ever changing market needs and high consumer demands. Manufacturers globally have to produce products at a faster rate without compromising on the quality. Simultaneously, manufacturers also have to find cost efficient solutions to increase the bottom line.

This has made it essential for manufacturers to capture data in real time across various functions of a manufacturing plant to identify bottlenecks, derive insights and make informed decisions quickly.

Vegam, with its smart factory solutions can provide high visibility and real time insights across functions like production, maintenance, inventory management and warehouse. This empowers manufacturers to make decisions that increase productivity, optimize inventory & maintenance costs and enhance product quality.

Read more

Better shopfloor visibility & smarter productivity tracking with Vegam

Real Time Productivity Management

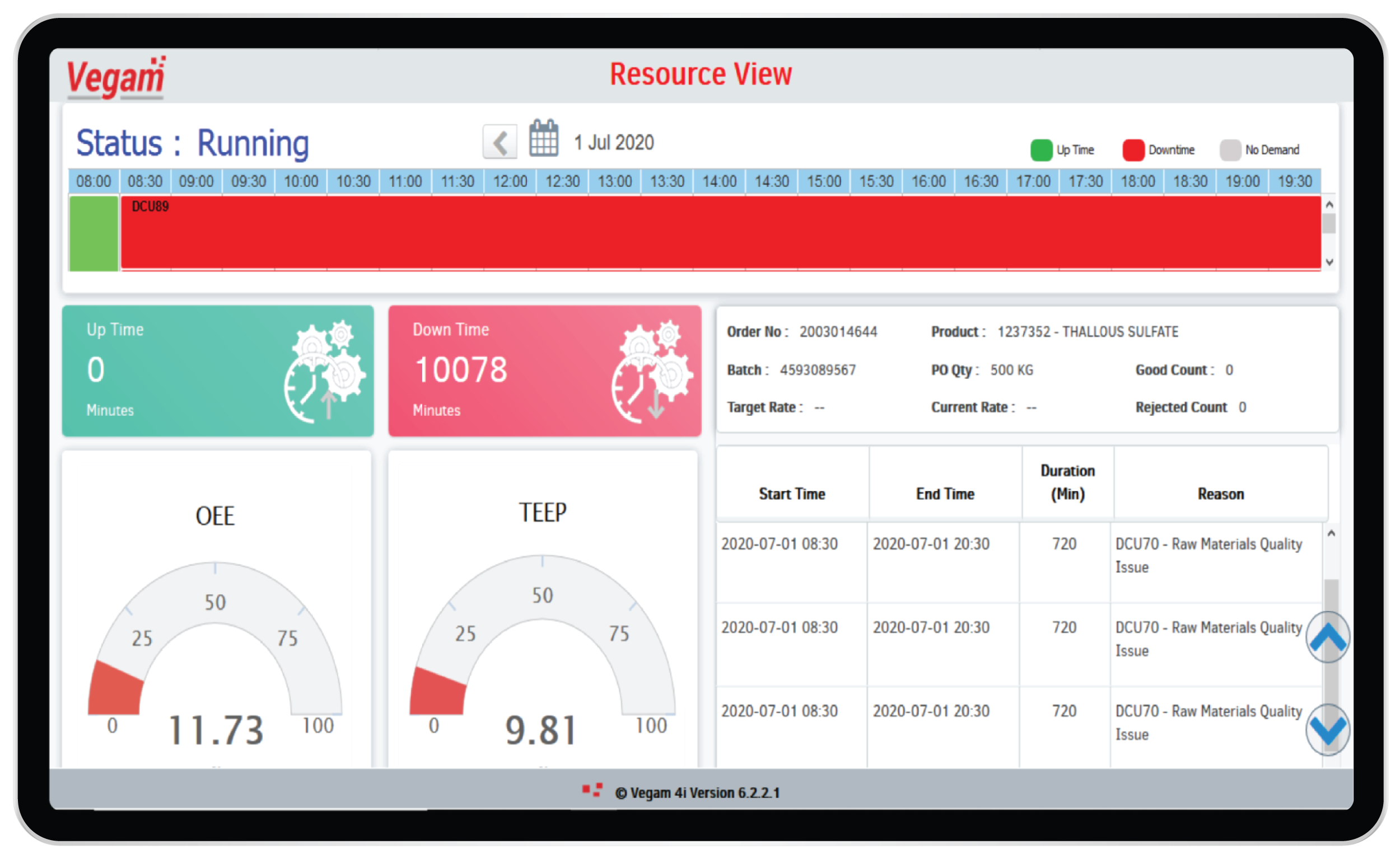

Discrete manufacturing plants have to strive continuously to reduce rejection and scraps, minimize the production cost and improve productivity. It is imperative to react quickly to abnormalities like machine failure, quality defects, high parts rejection and low OEE. To enable quick decision making requires shop floor data to be captured in real time with insights and full visibility in the manufacturing operations.

Current practices rely on paper based reporting of important parameters like production count, downtime. Production metrics are calculated manually at a later stage post the reporting. This practice results in a delay in reacting to any abnormalities or deviations in the production process, resulting in significant loss of material, time and cost hampering the overall business.

Vegam’s SFS Lite module enables the capturing of shop floor data and providing real time information about OEE, production/rejection count, WIP, machine downtimes. Historical and real time insights give the right information at the right time enabling decision makers to make informed decisions, significantly enhancing the productivity.

With the ability to seamlessly integrate across all technologies & complex systems in a manufacturing environment, Vegam’s systems also help optimize production assets and their life and minimize spend.

Schedule a Demo

Analytical Decision Making

Schedule a Demo

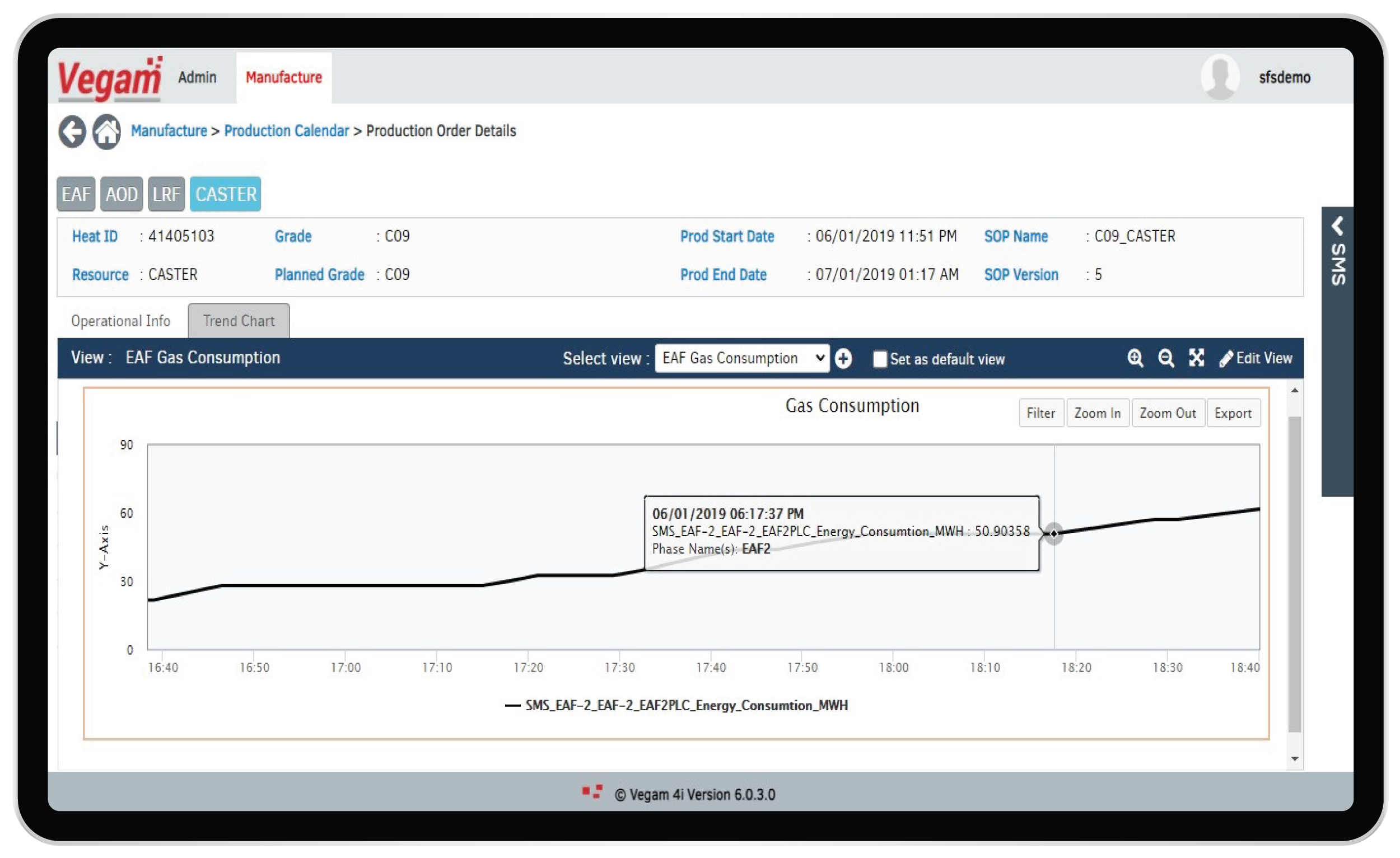

Digital transformation of manufacturing has resulted in generation of “information repositories” with data from various systems. Analysis of the information and associated facts can help un-earth insights that can predict future events. Artificial intelligence & Machine Learning techniques can be applied to develop predictive models which can generate prescriptive alerts & insights where in operations can be “Proactive” than “Reactive” to events.

Vegam Team brings expertise, skills and resources needed to work with the “Information repositories” and develop solutions that can generate data driven predictive triggers.

Alerts

Discrete manufacturing plants have to strive continuously to reduce rejection and scraps, minimize the production cost and improve productivity. It is imperative to react quickly to abnormalities like machine failure, quality defects, high parts rejection and low OEE. To enable quick decision making requires shop floor data to be captured in real time with insights and full visibility in the manufacturing operations.

Vegam’s SFS Lite module enables the capturing of shop floor data and providing real time information about OEE, Production/Rejection count, WIP, Machine Downtime. Historical and real time insights give the right information at the right time enabling decision makers to make informed decisions, significantly enhancing the productivity.

Schedule a Demo

Inventory Management

Schedule a Demo

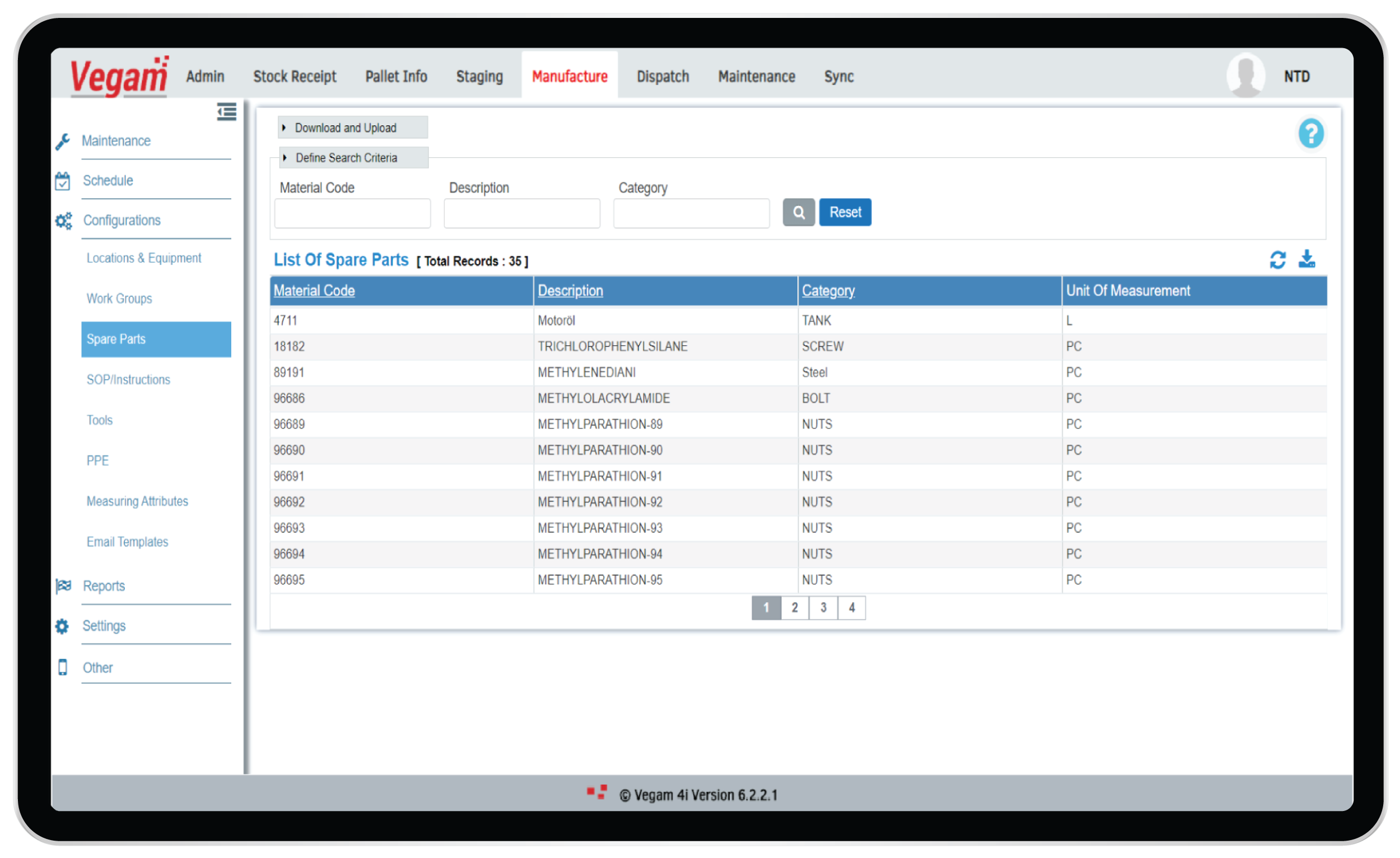

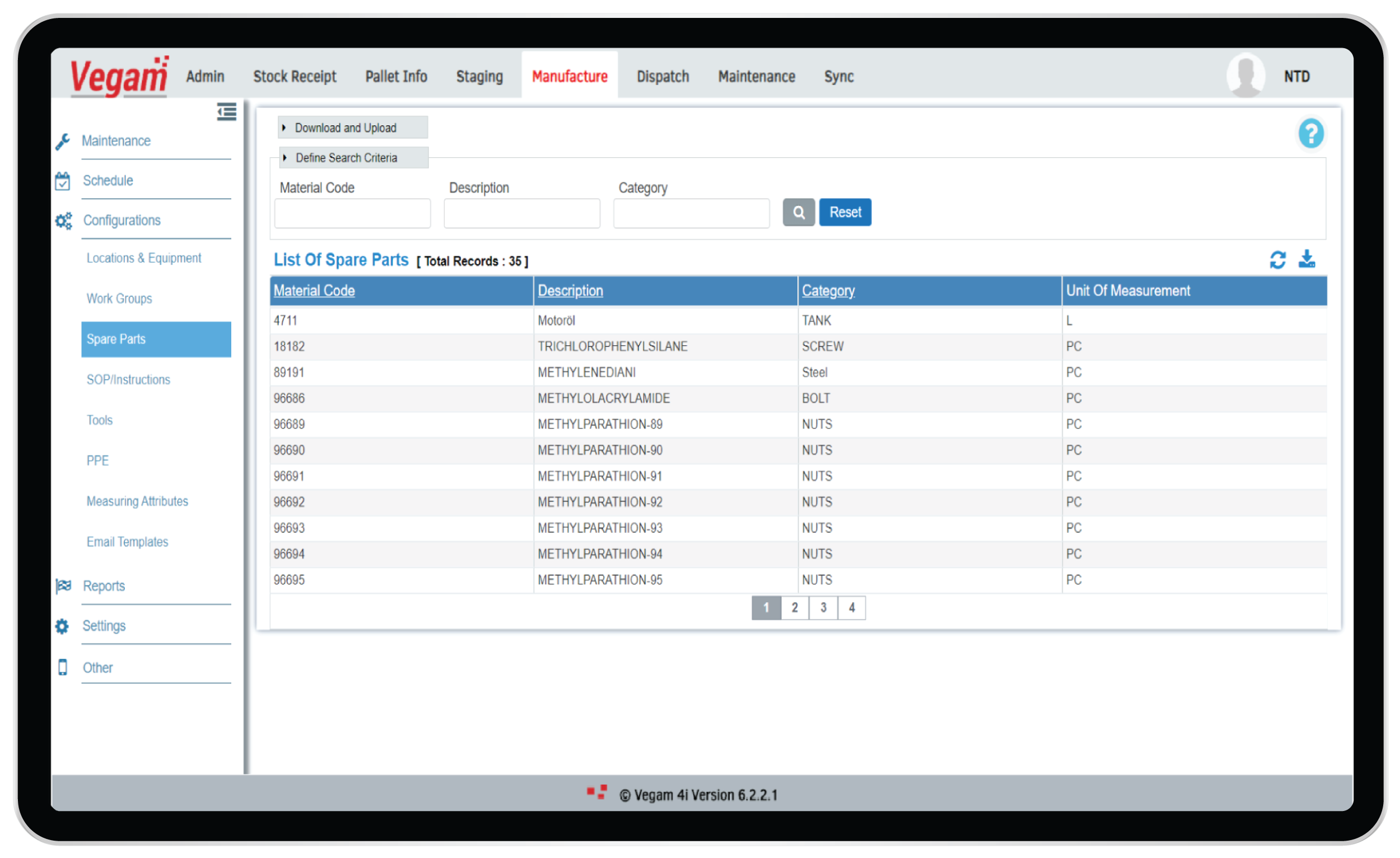

Inventory holding cost constitutes a major part of a manufacturing plant’s operational expenses. Manufacturers have to think of ways to reduce excessive storage of inventory. Simultaneously they have to ensure there is no production loss due to inventory stockout. It is important to optimize the overall inventory in a plant.

Vegam’s vWarehouse management solution gives real time visibility into the whole spare parts and inventory. Alerts can be configured based on inventory levels automatically triggering the purchase requisition of a spare part or machine. Full view of the inventory status helps take timely purchase decisions optimizing the overall inventory in a plant.

Tools & Machine Maintenance

Largely, maintenance activities are recorded on paper based systems in discrete industry with no real time tracking of the activities. Breakdown reporting happens through traditional methods like emails or phone calls, methods which are prone to errors, inefficiencies and miscommunication. This results in delayed response to equipment failures and increase in machine downtime in turn affecting the productivity of a plant.

Digitization of maintenance workflows to eliminate paper based reporting, automate routine tasks and predict machine failures can enhance the productivity of a plant.

Vegam’s vMaint4.0, a mobile first, IoT based solution offers modules to support paperless management of all aspects involved in managing maintenance activities. Vegam addresses the core challenges in adopting off-line or paper based solutions by bringing mobility and real-time capabilities. Integrated with IoT, Vegam supports advanced capabilities like “Predictive maintenance”, Artificial Intelligence & Machine Learning based alerts and triggers to operate the plants in a proactive mode.

Benefits of paper-less, IoT based maintenance include:

- Improved team management and optimized workforce

- Adherence to Preventive Maintenance (PM) Schedules

- Incident reporting through mobile app

- Spare Parts Management

- Real-time alerts and notifications

- Overall Equipment Efficiency (OEE)

- Predictive Maintenance

- Provider intervention management.

- Real time KPIs: MTTR, MTBF, Breakdown time

Schedule a Demo

One of the leading Adhesive

manufacturers in Asia was able

to achieve

10% Improvement

in productivity.

Customer success stories

Enabling Smart Maintenance Operations in Automotive Component Manufacturing

Case Study Customer Profile Pioneer in Adhesive technologies Headquartered in Europe with Annual revenue over 20 Billion USD Well established

Reach out to us